Excavator

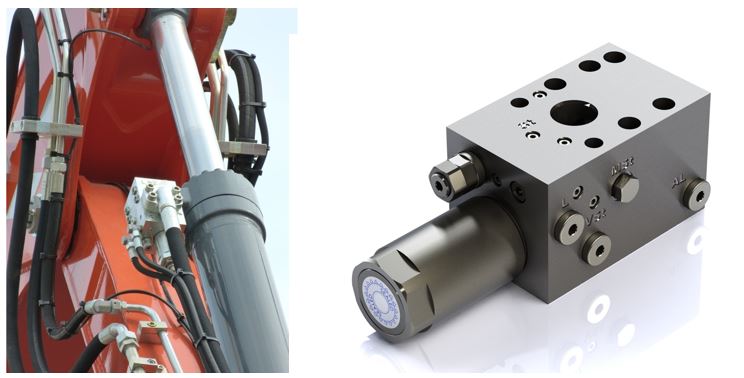

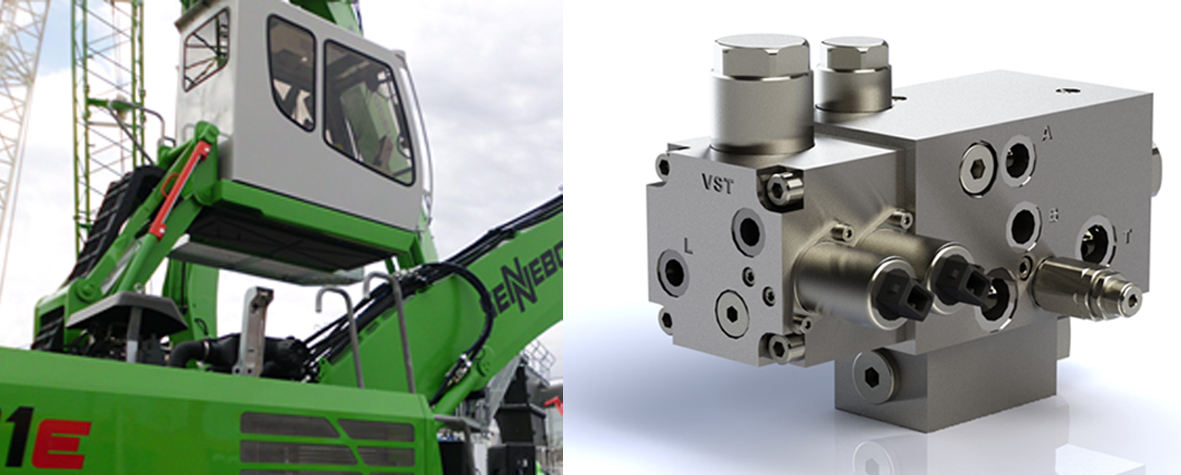

1 Pipe Rupture Protect Boom Cylinder

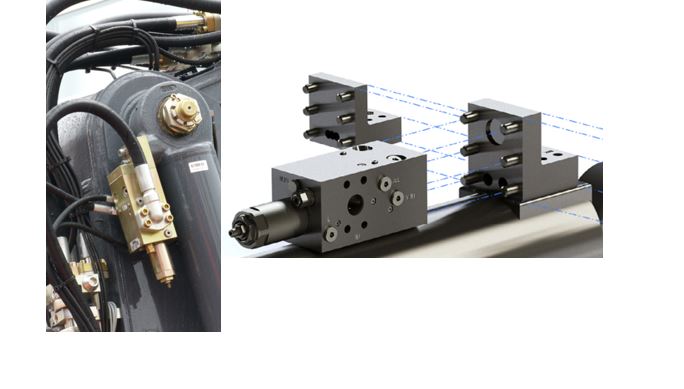

Pipe rupture protection as a modular system

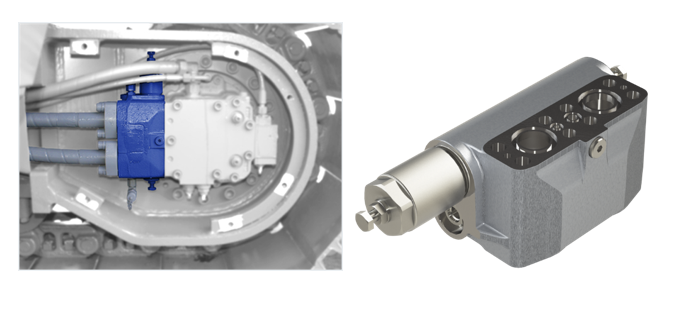

Brake valve for travel motors

Oil temperature regulator

6/2 way valve, Hydraulic separator

Valves for controlling quickcouplers

Pressure Control Valve, Cabin Control FC2-CC

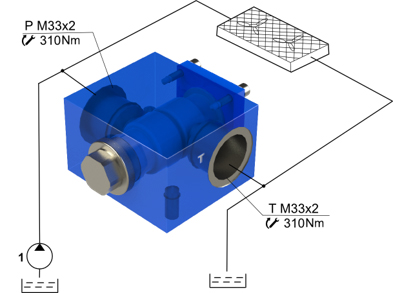

Priority valve FC1-1D

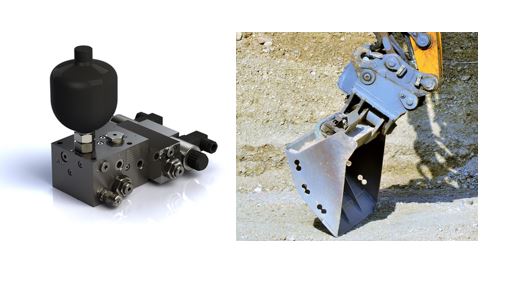

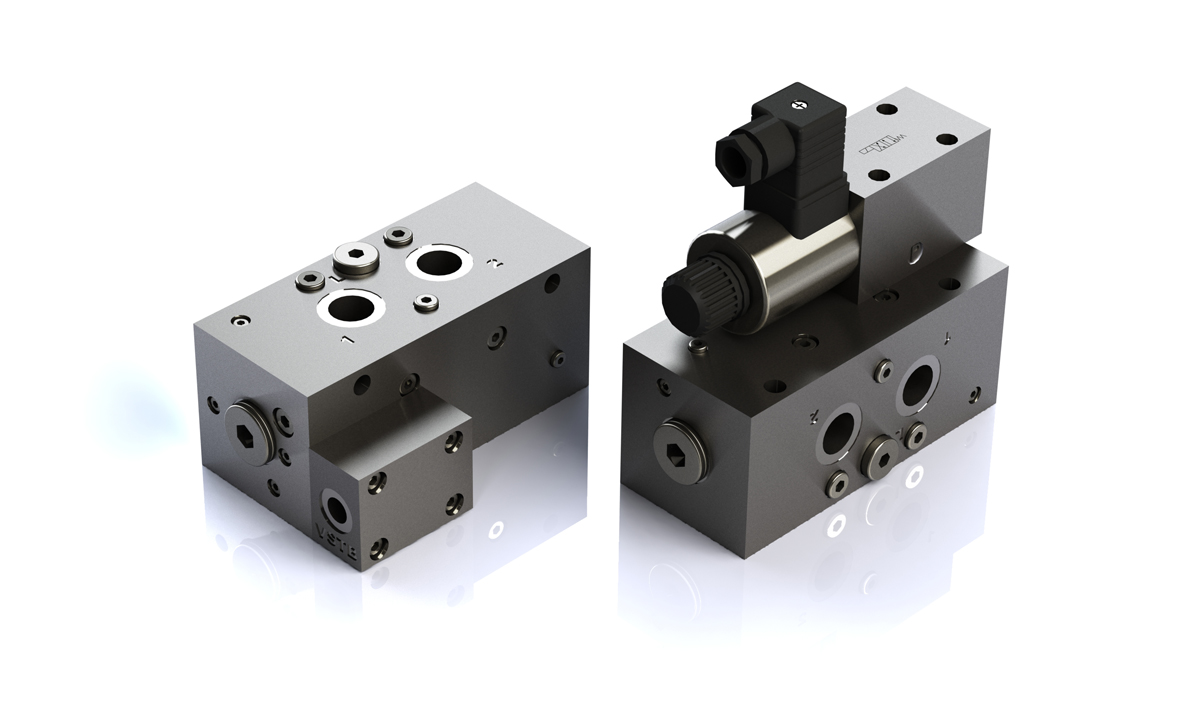

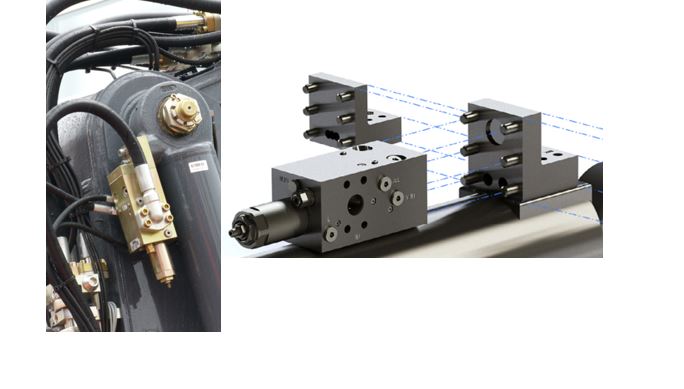

| Pipe rupture safety valves prevent uncontrolled cylinder movement in the event of a pipe or hose rupture. In some countries, pipe rupture valves are required by law when load or lifting work is carried out with a construction machine. They are used to position a boom accurately and stably and enable a uniform motion sequence. Pipe rupture valves can compensate for leakages at spools in main control systems of older construction machines. WESSEL pipe rupture safety valves are characterized by very good sensitivity and a very direct transmission behavior of the joystick movement. They are also always free of leakage oil. The pipe rupture valve in the standard version can be used for most standard applications. |

Pipe rupture safety valves prevent uncontrolled cylinder movement in the event of a pipe or hose rupture. In some countries, pipe rupture valves are required by law when load or lifting work is carried out with a construction machine. They are used to position a boom accurately and stably and enable a uniform motion sequence. Pipe rupture valves can compensate for leakages at spools in main control systems of older construction machines. WESSEL pipe rupture safety valves are characterized by very good sensitivity and a very direct transmission behavior of the joystick movement. They are also always free of leakage oil.

The pipe rupture valve in the standard version can be used for most standard applications.

More Informationen

Pipe rupture safety valves prevent uncontrolled cylinder movement in the event of a pipe or hose rupture. In some countries, pipe rupture valves are required by law when load or lifting work is carried out with a construction machine. They are used to position a boom accurately and stably and enable a uniform motion sequence. Pipe rupture valves can compensate for leakages at spools in main control systems of older construction machines. WESSEL pipe rupture safety valves are characterized by very good sensitivity and a very direct transmission behavior of the joystick movement. They are also always free of leakage oil.

The pipe rupture valve in the standard version can be used for most standard applications.

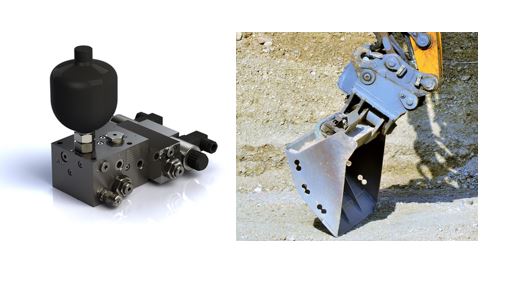

More Informationen The pipe rupture protection in modular design can be used for most standard applications. In contrast to the standard design LHB-4N, the connection Z (cylinder) of the pipe rupture protection LHB-4F is flange-mounted and thus interchangeable with other connection sizes.

CD 61 and CD 62 in 3/4″, 1″ and 1 1/4″.

The pipe rupture protection in modular design can be used for most standard applications. In contrast to the standard design LHB-4N, the connection Z (cylinder) of the pipe rupture protection LHB-4F is flange-mounted and thus interchangeable with other connection sizes.

CD 61 and CD 62 in 3/4″, 1″ and 1 1/4″.

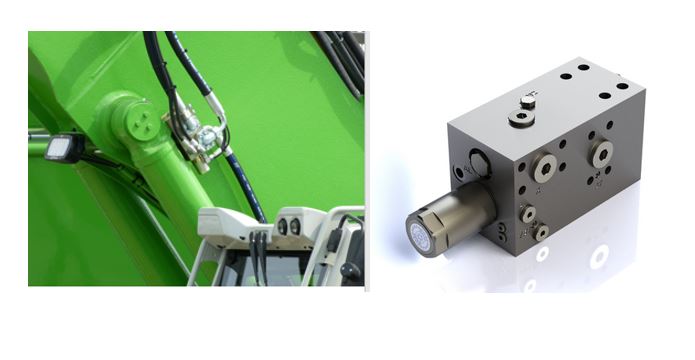

The LHB-3R type pipe rupture protection has an internal regeneration circuit. The returning volume flow is accumulated by an internal non-return valve and directed to the rod side as required.

This allows the cylinder to be retracted without the need for a pump flow rate.

More Informationen

The LHB-3R type pipe rupture protection has an internal regeneration circuit. The returning volume flow is accumulated by an internal non-return valve and directed to the rod side as required.

This allows the cylinder to be retracted without the need for a pump flow rate.

More Informationen Brake valves are used as safety valves in hydraulically driven construction machinery. They prevent excessive speeds when traveling downhill. At the same time, they protect the travel motor from excessive speeds. The brake valve is flange-mounted either on the travel motor of a wheeled excavator or on the drive motors of a crawler excavator. It can also be used for rotary motors of other applications.

More Informationen

Brake valves are used as safety valves in hydraulically driven construction machinery. They prevent excessive speeds when traveling downhill. At the same time, they protect the travel motor from excessive speeds. The brake valve is flange-mounted either on the travel motor of a wheeled excavator or on the drive motors of a crawler excavator. It can also be used for rotary motors of other applications.

More Informationen

The oil temperature controller enables temperature-dependent control of an oil flow. With the aid of a thermocouple, a valve spool is steplessly switched from its open from its open position to a closed position. This causes a pressure increase in the cooling pump circuit, which leads to an increase in the flow rate through the cooler. flow rate through the cooler. More Informationen

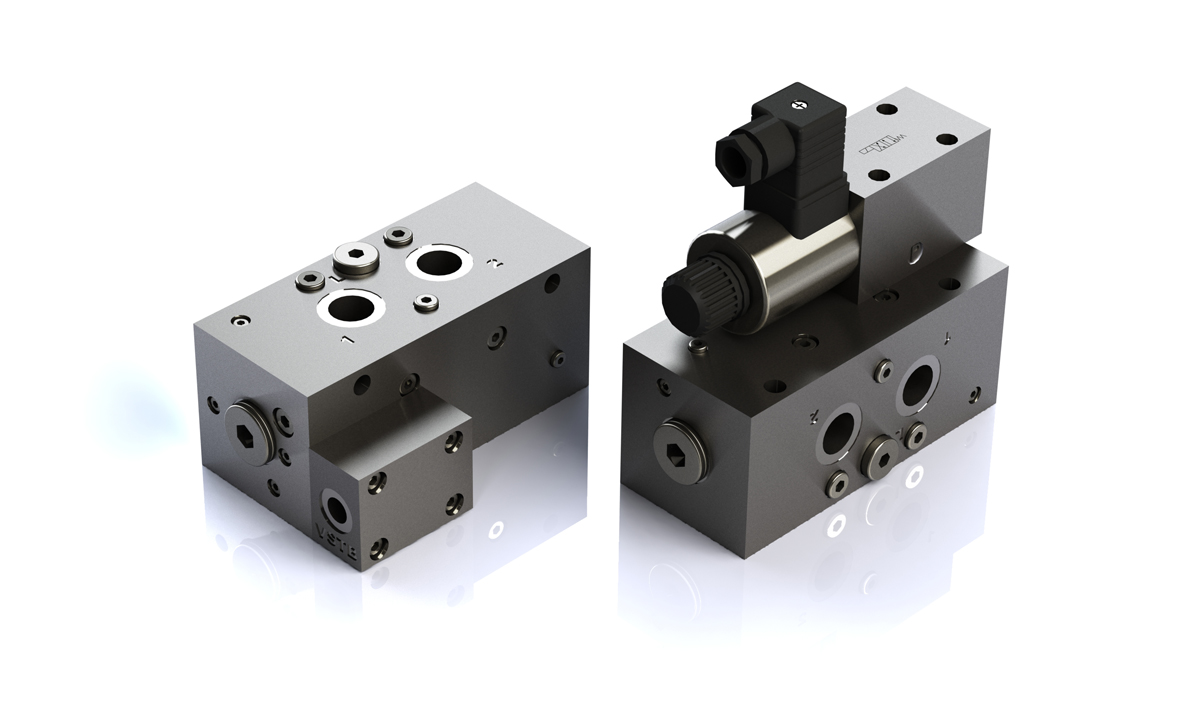

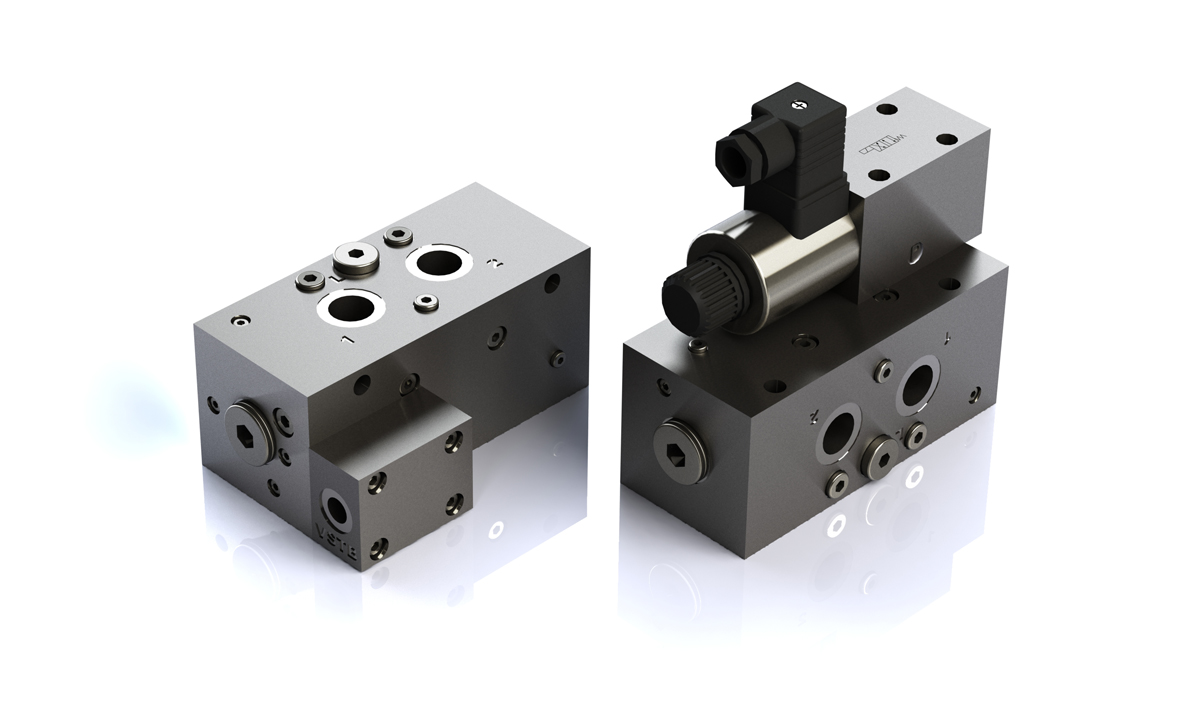

With a 6/2 or 6/3 directional control valve, the volume flow downstream of a main section can be distributed to either 2 consumers.

The directional control valves are available in two versions:

Directional valve 6/3 with one middle position

Directional valve 6/2 without center position

Without center position, the main consumer is controlled in the unswitched state of the directional valve. In the switched state, the new additional consumer is operated. Switching is done hydraulically or electrically. In the electric version, the pilot pressure required for the switching operation is taken from the high-pressure supply line, so that no additional pilot pressure needs to be provided.

The valves are not leakage-free. Pressure relief devices for the additional consumer must be installed externally.

In version 6/3, the center position is assumed unactuated. In this position, all inputs and outputs are blocked against each other.

More Information

With a 6/2 or 6/3 directional control valve, the volume flow downstream of a main section can be distributed to either 2 consumers.

The directional control valves are available in two versions:

Directional valve 6/3 with one middle position

Directional valve 6/2 without center position

Without center position, the main consumer is controlled in the unswitched state of the directional valve. In the switched state, the new additional consumer is operated. Switching is done hydraulically or electrically. In the electric version, the pilot pressure required for the switching operation is taken from the high-pressure supply line, so that no additional pilot pressure needs to be provided.

The valves are not leakage-free. Pressure relief devices for the additional consumer must be installed externally.

In version 6/3, the center position is assumed unactuated. In this position, all inputs and outputs are blocked against each other.

More Information

The flow control valve can be used to operate single-acting auxiliary consumers such as hammers and mowers on one machine.

The flow control valve of the FC1-1N or FC1-2N design is a 2-way or 3-way flow controller (pressure compensator) for volume flows up to 550 l/min. The valve can thus be used in LS or NFC systems. The additional consumer can be operated simultaneously to the normal machine functions. The volume flow and pressure to the auxiliary consumer is independent of the pressure and volume flow of the main consumers in the machine.

In both operating modes, the additional consumer can be activated electrically or hydraulically or remain switched on permanently. The size of the volume flow to the additional consumer can be set manually by the user. Likewise, the maximum pressure limitation for the additional consumer is set by the user. The pressure limitation is based on the pressure cut-off principle and thus regulates the volume flow via the current control function until the pressure falls below the set maximum pressure.

A preloaded check valve or throttle check valve can be attached to port H for the additional consumer. This

check valve prevents the consumer from influencing the control of the flow control valve and also ensures that the flow control valve does not

the flow control valve is always preloaded as far as necessary for trouble-free operation when operating consumers with low starting pressures or pulling loads.

necessary for trouble-free operation (> 8 bar).

Because leakage occurs at spool-type directional control valves in the neutral switching position, it can lead to slow lowering of the boom or load. If this is not desired, it can be prevented by leakage-free shut-off.

The shut-off is absolutely leakage-free. The design is of seat-type construction with hardened components. An integrated pressure relief valve protects the consumer from excessive pressures in the shut-off state.

More Information

Because leakage occurs at spool-type directional control valves in the neutral switching position, it can lead to slow lowering of the boom or load. If this is not desired, it can be prevented by leakage-free shut-off.

The shut-off is absolutely leakage-free. The design is of seat-type construction with hardened components. An integrated pressure relief valve protects the consumer from excessive pressures in the shut-off state.

More Information Quick coupler systems are used for easy changing of tools on construction machines without the operator having to leave the cabin for this purpose. The main functional part of the quickcoupler system is a hydraulic cylinder that opens and closes the quickcoupler lock for the changing process and securely locks the quickcoupler when closed.

More Information

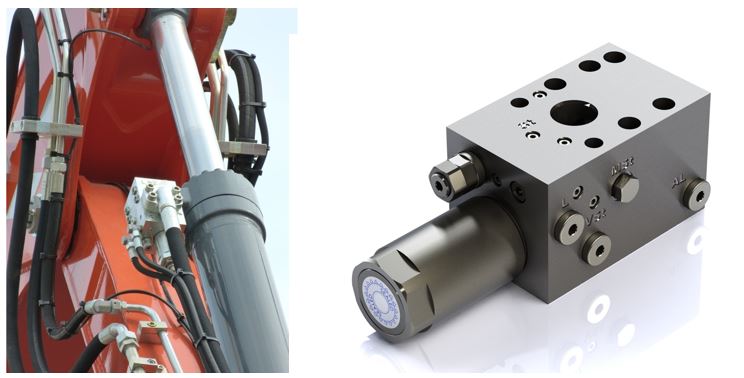

Quick coupler systems are used for easy changing of tools on construction machines without the operator having to leave the cabin for this purpose. The main functional part of the quickcoupler system is a hydraulic cylinder that opens and closes the quickcoupler lock for the changing process and securely locks the quickcoupler when closed.

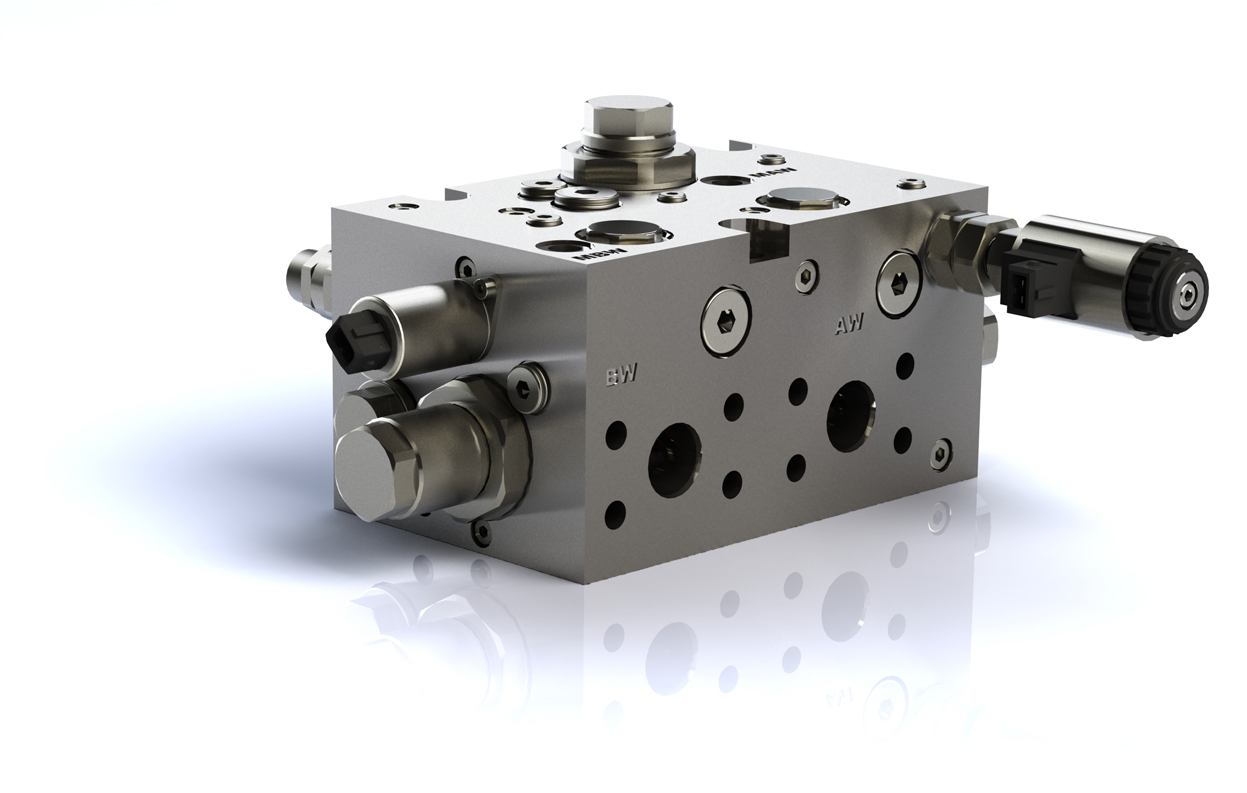

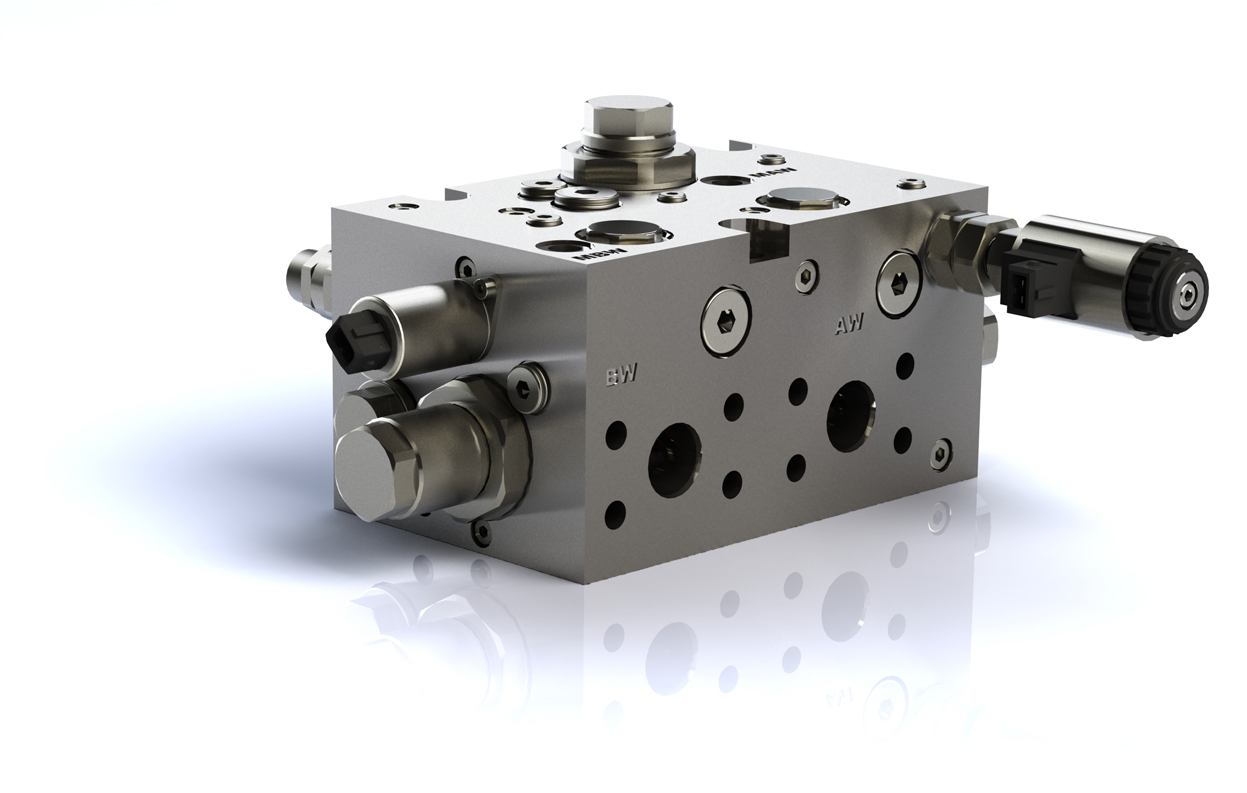

More Information The valve can be used to operate two attachments independently of each other. The 4/3 directional control valve is controlled by energizing the proportional pilot valves VStA or VStB.

A double-acting attachment such as a scissors (opening/closing) is thus supplied via the A and B connections. By energizing the proportional pilot valve VSt1, a volume flow controlled via an upstream pressure compensator is provided at port H. This volume flow can be used for the operation of single-acting attachments.

This can be used for the operation of single-acting consumers, such as hammers or a compressor.Both consumers can be limited in maximum operating pressure via pressure relief valves, which operate according to the pressure cut-off principle. The upstream 2-way pressure compensators keep the pressure difference constant. Thus, the consumers are supplied with the required volume flow independent of the load. The valve provides an internal LS signal for the pump./

Mehr Informationen

The valve can be used to operate two attachments independently of each other. The 4/3 directional control valve is controlled by energizing the proportional pilot valves VStA or VStB.

A double-acting attachment such as a scissors (opening/closing) is thus supplied via the A and B connections. By energizing the proportional pilot valve VSt1, a volume flow controlled via an upstream pressure compensator is provided at port H. This volume flow can be used for the operation of single-acting attachments.

This can be used for the operation of single-acting consumers, such as hammers or a compressor.Both consumers can be limited in maximum operating pressure via pressure relief valves, which operate according to the pressure cut-off principle. The upstream 2-way pressure compensators keep the pressure difference constant. Thus, the consumers are supplied with the required volume flow independent of the load. The valve provides an internal LS signal for the pump./

Mehr Informationen The flow control valve is an ideal combination with the WESSEL Tool Control plus and allows a proportional adjustment of volume flow (max. 400 l/min) and pressure (max. 400 bar) for double-acting attachment (milling, Mulcher, Alligator bucket). The attachment can be operated simultaneously with the normal machine functions (please consider the maximum flow rate of the machine). The inlet is designed with a 3-way pressure compensator controlled by an electrically-adjustable proportional orifice. The proportional valve is supplied by the inlet volume flow. A preceding high pressure pressure reducing valve ensures stability with working pressure up to 400 bar. The pressure compensator is placed in the bypass and regulates the remaining flow to the return side. The return flow from the tool is routed with low loss through check valves in bypass to the orifice back to the main control valve. The maximum operating pressure is adjusted proportionally by means of a pilot valve. When the pressure exceeds, the pressure compensator opens to the opposite side.

Mehr Informationen

The flow control valve is an ideal combination with the WESSEL Tool Control plus and allows a proportional adjustment of volume flow (max. 400 l/min) and pressure (max. 400 bar) for double-acting attachment (milling, Mulcher, Alligator bucket). The attachment can be operated simultaneously with the normal machine functions (please consider the maximum flow rate of the machine). The inlet is designed with a 3-way pressure compensator controlled by an electrically-adjustable proportional orifice. The proportional valve is supplied by the inlet volume flow. A preceding high pressure pressure reducing valve ensures stability with working pressure up to 400 bar. The pressure compensator is placed in the bypass and regulates the remaining flow to the return side. The return flow from the tool is routed with low loss through check valves in bypass to the orifice back to the main control valve. The maximum operating pressure is adjusted proportionally by means of a pilot valve. When the pressure exceeds, the pressure compensator opens to the opposite side.

Mehr Informationen In many hydraulic applications, unnecessary energy losses or even performance losses are caused by high return pressures. As a result, the tool does not have the full power available, and the pump is partially swiveled back by the power control, so that speed losses also have to be accepted. If cylinders are used in the attachment tool, volume flows quickly result on the bottom side, which double the maximum pump volume flow. The main control valves are not necessarily designed for this. These losses can be significantly minimized by additional direct relief to the tank using a 3/3-way valve. A reduction of e.g. 30 bar at a volume flow of 400 l/min creates more than 20 kW additional power or correspondingly reduced losses. The valve thus works as a bypass valve to the main control block. The valve is available in 3 sizes: 137.901.002.9 G1″ 200 l/min 138.901.001.9 G1 ¼” 400 l/min 139.904.001.9 SAE 1½” 600 l/min

more information

In many hydraulic applications, unnecessary energy losses or even performance losses are caused by high return pressures. As a result, the tool does not have the full power available, and the pump is partially swiveled back by the power control, so that speed losses also have to be accepted. If cylinders are used in the attachment tool, volume flows quickly result on the bottom side, which double the maximum pump volume flow. The main control valves are not necessarily designed for this. These losses can be significantly minimized by additional direct relief to the tank using a 3/3-way valve. A reduction of e.g. 30 bar at a volume flow of 400 l/min creates more than 20 kW additional power or correspondingly reduced losses. The valve thus works as a bypass valve to the main control block. The valve is available in 3 sizes: 137.901.002.9 G1″ 200 l/min 138.901.001.9 G1 ¼” 400 l/min 139.904.001.9 SAE 1½” 600 l/min

more information The 2/2 directional valve is used to connect or disconnect a hydraulic line (similar to ball valve). It is a pilot controlled valve, which is designed

The 2/2 directional valve is used to connect or disconnect a hydraulic line (similar to ball valve). It is a pilot controlled valve, which is designedfor high pressure and high volume flow and thus suitable for mobile applications. In many hydraulic applications, high return pressures cause unnecessary energy loss or even loss of power. Through an additional direct

relief to the tank using a 2/2 directional control valve, these losses can be minimized to a great extent.

A typical application is, e.g. in the case of construction machinery, to connect the return line of a hydraulic tool to the tank bypassing the main

control valve. When operating a hydraulic hammer, this is often necessary for achieving trouble–free functionality of the equipment and in

other applications such as scrap– and demolition shears, a clear increase in power is achieved. more information

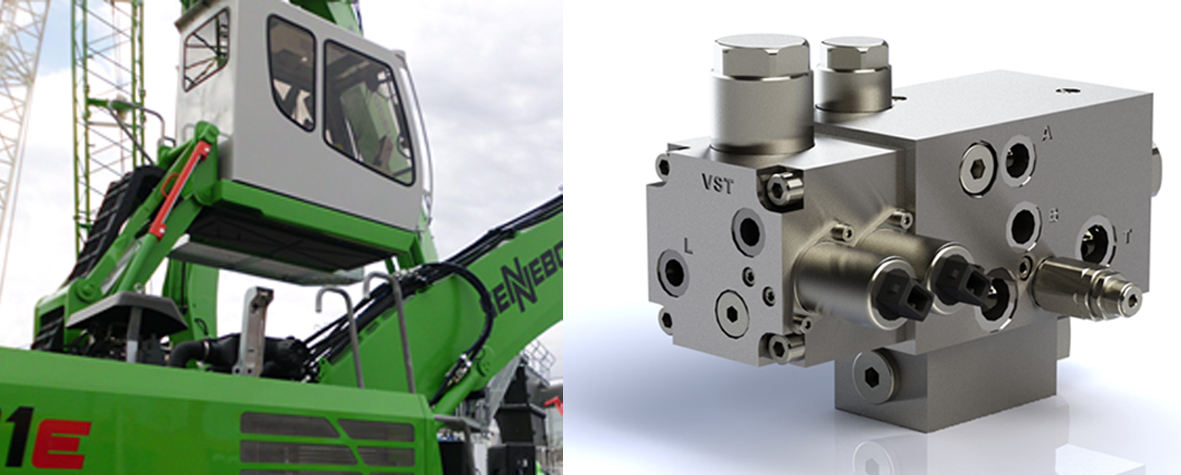

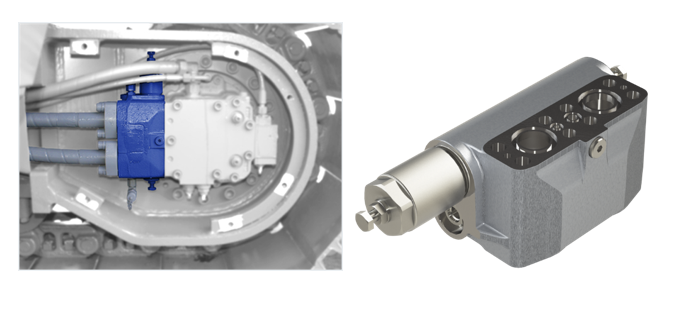

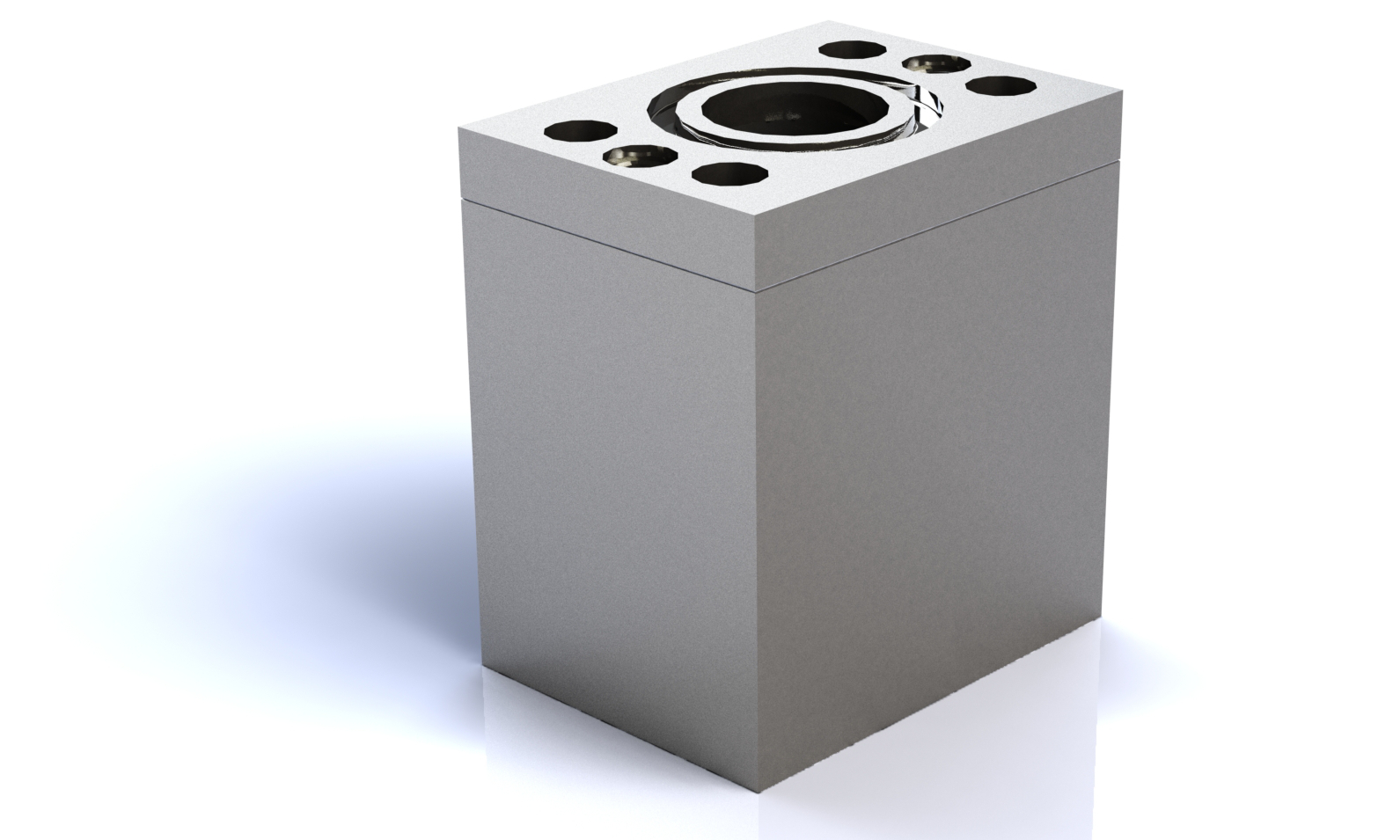

Raising and lowering the operator’s cab often places high demands on the comfort function. Smooth starting and braking are required, as is leak-free holding in the raised position. The cab control is a 4/3 directional control valve designed to operate on a fixed displacement pump. The integrated inlet pressure compensator reduces pressure losses to a minimum. The main spool can be adjusted electrically-proportionally, and an internal circuit imposes a ramp on the spool when switched. Output A is locked leak-free by a pilot-operated check valve. Raising and lowering the operator’s cab often places high demands on the comfort function. Smooth starting and braking are required, as is leakage oil-free holding in the raised position. The cab control is a 4/3 directional control valve designed to operate on a fixed displacement pump. The integrated inlet pressure compensator reduces pressure losses to a minimum. The main spool can be adjusted electrically-proportionally, and an internal circuit imposes a ramp on the spool when switched. Output A is locked leak-free by a pilot-operated check valve.

more information

Raising and lowering the operator’s cab often places high demands on the comfort function. Smooth starting and braking are required, as is leak-free holding in the raised position. The cab control is a 4/3 directional control valve designed to operate on a fixed displacement pump. The integrated inlet pressure compensator reduces pressure losses to a minimum. The main spool can be adjusted electrically-proportionally, and an internal circuit imposes a ramp on the spool when switched. Output A is locked leak-free by a pilot-operated check valve. Raising and lowering the operator’s cab often places high demands on the comfort function. Smooth starting and braking are required, as is leakage oil-free holding in the raised position. The cab control is a 4/3 directional control valve designed to operate on a fixed displacement pump. The integrated inlet pressure compensator reduces pressure losses to a minimum. The main spool can be adjusted electrically-proportionally, and an internal circuit imposes a ramp on the spool when switched. Output A is locked leak-free by a pilot-operated check valve.

more information The valve is installed in the return line right before the tank inlet. The oil flowing back from the consumers is preloaded and is therefore available for suction functions in order to prevent cavitation. The valve is available with different preload pressures (3 bar, 4.5 bar). Customized housings are possible.

more information

The valve is installed in the return line right before the tank inlet. The oil flowing back from the consumers is preloaded and is therefore available for suction functions in order to prevent cavitation. The valve is available with different preload pressures (3 bar, 4.5 bar). Customized housings are possible.

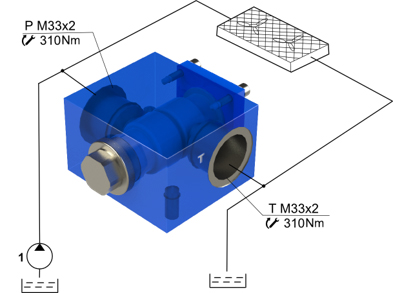

more information The priority valve is used to supply an additional consumer with a preferred volume flow. The residual volume flow is provided to supply the existing main functions on the machine. The priority valves are suitable for open-center and closed-center systems. The divided volume flow to the additional consumer has priority over the main functions. The valve is flanged directly to the pump or to the pump input of the main control. The combination with other valves enables a wide range of applications. The valve is normally combined with other valves, such as flow control valve FC1X-2P.

more information

The priority valve is used to supply an additional consumer with a preferred volume flow. The residual volume flow is provided to supply the existing main functions on the machine. The priority valves are suitable for open-center and closed-center systems. The divided volume flow to the additional consumer has priority over the main functions. The valve is flanged directly to the pump or to the pump input of the main control. The combination with other valves enables a wide range of applications. The valve is normally combined with other valves, such as flow control valve FC1X-2P.

more informationWESSEL-HYDRAULIK – Your competent partner

Contact person

- Markus Tugendhat